River Tunnel

Salt Lake City International Airport

In November of 2018, SLCDA engaged Gordon Huether Studio to develop an artistic concept to be applied to the tunnel that was planned to connect the Main Concourse to the North Concourse.

This project has been broken up into phases to ensure that the project was developed in the most successful way possible.

In the Schematic Design Phase, the team was tasked with fully understanding the space to present three different concepts for the stakeholders to choose from. This required a thorough understanding of the architecture and engineering of the space to ensure the concepts being presented were feasible to execute within the space without major modifications to the existing design. With the support of the team, Gordon developed more concepts than required and ultimately worked with stakeholders to choose the River Tunnel Concept.

Lighting was challenging since the concept was to be applied to the ceiling rather than the walls. To apply proper lighting to the concept, we couldn’t light from the floor without creating “dead” spots or visual nuisances to passengers. The best option to light the concept was to apply backlighting. The team chose to use light panels to create a false ceiling.

Because of the decision to utilize “Cooledge Light Panels” for the false ceiling, specific parameters were identified that assisted the team in narrowing down the installation approach. The size limits of the panels identified where unistrut could be placed to allow attachment points of the artwork. The artwork then had to be revisited to ensure that there was enough support for each element. All revisions could be made without affecting the artist’s aesthetic goal.

The next phase was Design Development, where we were to define the final cost and fabrication and installation methods. There were many factors associated with the decision to move forward with the River Tunnel Concept. The biggest factor considered was that the concept utilized materials, technology, and fabricators/installers to execute the idea, which we were already very familiar with. The River Tunnel concept took the same methods and materials that were used for The Canyon, applied to vertical walls, and modified to work on the horizontal ceiling of the tunnel. As the team dove deeper into the development of the details of this concept, many additional complications showed themselves to the team, which we used as opportunities to refine the concept further.

Gordon recognized that the space was as visually immersive as possible, but if we could touch on the sense of hearing as well, that would immerse the passengers into the artwork even further. We engaged sound consultants and developed a plan to integrate a separate sound system that worked alongside the airport announcement system.

We produced many renderings and animations through this process to visualize how each element affected the space. When we had taken the concept as far as we could, we recognized that to fully understand the concept and identify any hidden costs, we needed to mock the concept up. To mock this concept up properly, we fabricated a 20-foot-long section of the tunnel. We added One Hat One Hand to the team to assist in building the section of the tunnel. We engaged each associated vendor and fabricator to fabricate their specified elements for the mockup, and we assembled them all at the Gordon Huether Studio for client review. When it was all complete, the client was fully confident in the concept and ready to move into Fabrication.

As we worked through the development of the concept, Gordon flushed out as many opportunities to create a fully immersive experience for the passengers.

We found that we could customize the Cooledge Panels, and make them blue.

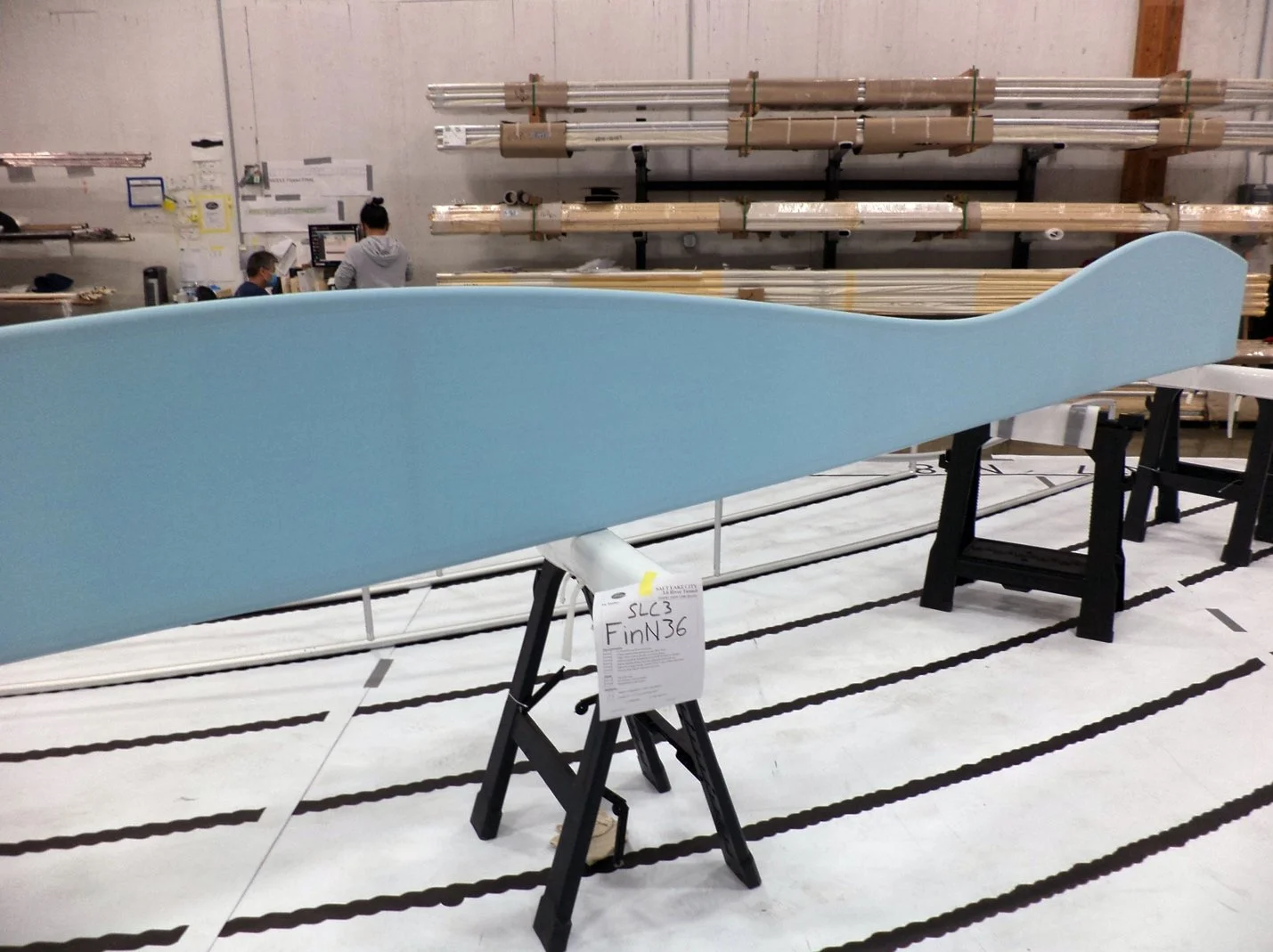

We found that the “fins” used as the artwork, could also be fabricated in blue.

We found that there was an opportunity to provide blue uplighting along the walls.

We found that we could have the walls painted blue.

We even worked with the architect to develop a custom terrazzo for the floor that integrated blue to assist with the immersive river experience.

Because we had been so thorough in our Design Development Phase, executing an agreement with clients and vendors for The Fabrication Phase was very simple. All details had been defined, costs were easily identified, minimal contingency budgets were required, and schedules were easy to identify. There was very little left unknown, which made the Fabrication Phase easy to navigate and manage. GHS was responsible for the fabrication of the artwork, which was contracted out to ETS who collaborated with Rainier Industries.

We completed The Fabrication Phase approximately two years prior to the space being ready for installation. In April of 2024, the space was ready, and ETS completed the installation in less than six weeks. Due to all of the planning and work we did as a team in the initial stages of this project, there were no surprises or problems to solve relative to the installation. This installation was very successful.

Current Status:

There is no further work required on site for this project. We are currently in the wrap up stage of the project, writing any required supporting documents, performing financial analysis, and reviewing files prior to archiving.

Estimated Timeline:

Currently the River Tunnel is scheduled to open to passengers on October 22, 2024.

DPS’ Client: Gordon Huether Studio

Final Client: Salt Lake City International Airport

DPS’ Role:

When this project was first brought to us, I still worked as an employee at Gordon Huether Studio. When I transitioned over to working for Gordon as a consultant, this project remained my responsibility. I was responsible for:

All contracting with Clients, Subcontractors, and Consultants

Support Gordon as he developed his concepts to ensure feasibility

Coordination and management of all aspects of the team

Research into new products and fabrication methods

Budget Development

Schedule Development

When we were contracted to complete the Mockup, I worked to develop that plan and engage all required subcontractors. I was needed onsite in Salt Lake City for Phase 1 installations when it came time to assemble the Mockup, so Brian Scharf from Brave Designs took over the Project Management of this project at this time. Brian had been responsible for the digital development of all of the renderings and animations and had been intimately involved in the project to this point. Brian managed the project until I completed the Phase 1 installations and was available to take the project back about halfway through the fabrication effort in May 2021. After that, I continued to manage the project with:

Fabrication Review for quality control

Fabricator Management

Installation Planning and logistics coordination

Site contractor coordination

Onsite Installation oversight